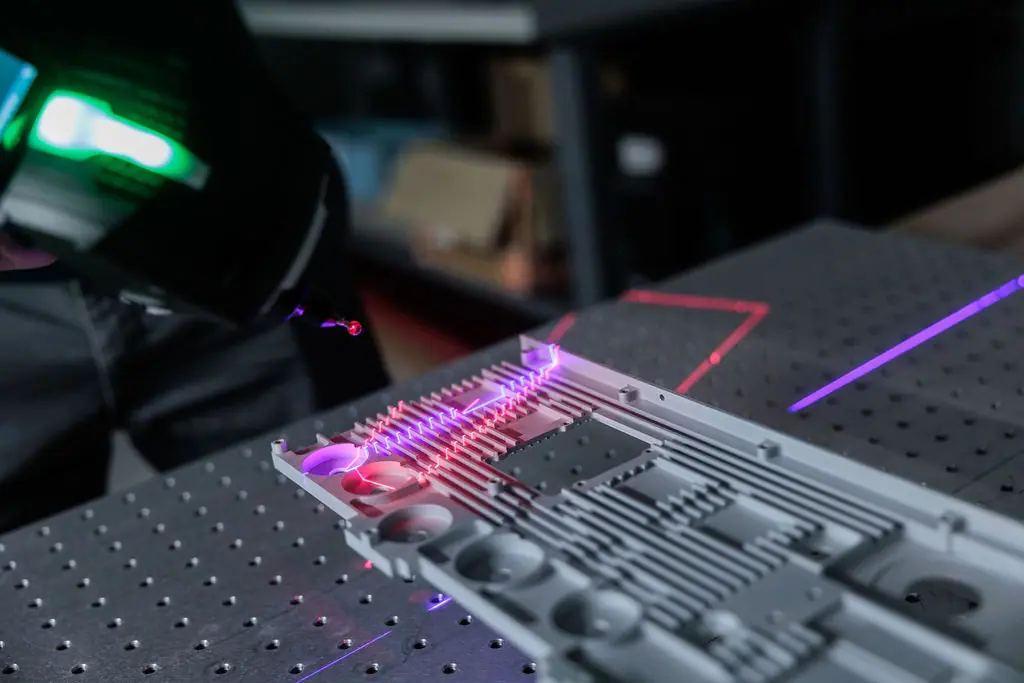

- Surface mount technology assembly line with automated stencil printer, pick and place, AOI, and X-Ray inspection capabilities

- Lead forming, tinning, component locator and selective solder for through-hole board assembly

- Flexible circuit expertise

From board assembly to fabrication to magnetics to mechanical assembly and everything in between—we do it all under one roof. Our manufacturing goal is to make whatever we can in-house and to continue developing our internal capability. This allows us to remain flexible and nimble, to achieve rapid prototyping and production, and to collaborate with all departments—delivering products that perform and protect in demanding domains.

We use automation where it makes sense to do so, but our products are hand-made. With a focus on our people, we ensure our expert staff is cross-trained and has the tools necessary to skillfully complete procedures. Our dedicated, experienced pros are committed to quality and are the secret sauce behind our power solutions.

Manufacturing with a Quality Mindset

We’re dedicated to meeting quality and safety standards. At ACT, our quality system is certified to AS9100D and ISO 9001:2015 and valid for the design and manufacturing of rugged power supplies and electronic devices. As one of our brand values, quality is always top of mind when building power solutions that are depended on to perform and protect. Our quality assurance operations flow into our manufacturing process by getting inspected and tested throughout our build process to ensure the highest quality products leave our building.

As a manufacturer of products with components that may contain gold, tantalum, tin, or tungsten, ACT is committed to operating in a socially responsible way. It is ACT’s policy to refrain from purchasing from any known conflict sources and we expect our suppliers to adhere to the same standards. We have notified our suppliers of our policy on conflict minerals and have asked each supplier to provide us with a confirmation of the conflict-free status.