The modern military depends on electronic systems, and power supply challenges often arise if the ideal solution is not in place. That is why the reliability and resilience of rugged power supplies are so important for military applications. Rugged power supplies with military specifications and standards play a crucial role in ensuring uninterrupted power and performance in harsh environments when needed most.

Understanding rugged power supplies and how they apply to these harsh environments will help address the unique challenges posed in these demanding situations.

In extremely harsh environments such as military situations, a stable power supply is essential, and you need something dependable enough to withstand the setting and conditions. Unlike standard commercial power solutions, rugged power supplies are crafted meticulously to withstand varying extreme temperatures and excessive vibrations and shocks that are often prevalent in military environments.

Military-grade power supplies must be immensely durable and reliable, two key factors for mission-critical applications where traditional power sources might falter. Ruggedized power supplies are engineered from robust materials and components, including specialized coatings and casings. These features, which are not found in typical power supplies, provide protection against moisture, dust, and corrosive elements, among other potentially compromising factors.

Overall, the right ruggedized power supply can help in mission success by ensuring devices are powered as expected, no matter where or how the military application takes place.

If you are an engineer looking to spec out a military-grade project that requires power supplies, you know that power supply challenges can pose issues when specific conditions aren’t met or considered. The following factors can help guide your decision.

Military operations are not limited to a single type of environment — they occur across diverse landscapes, meaning electronic systems are exposed to varying harsh conditions.

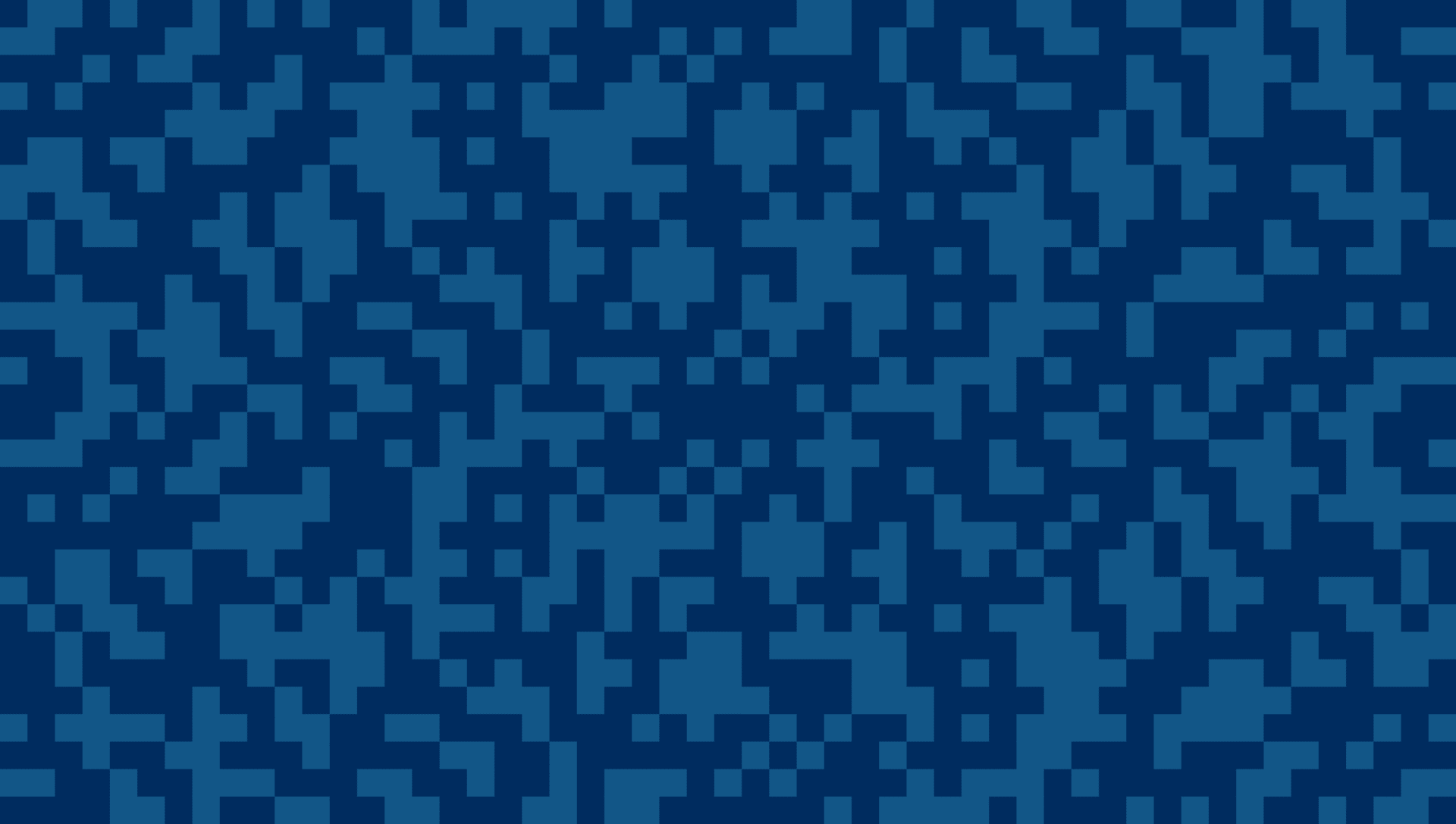

The right rugged power supply is designed to operate seamlessly without compromise due to the effects of extreme temperatures, ranging from desert heat to freezing winds. These environments can also involve high levels of humidity, sand, salt, and moisture exposure, so ruggedized power supplies must withstand these environmental factors, too. Beyond the construction of the power supply equipment itself, the power supply’s enclosure is essential, as it will help shield the power equipment from exposure to moisture and other elements.

Extreme precision is necessary for stable and predictable power delivery to critical electrical components in military applications. Therefore, power supplies must meet stringent electrical specifications. These specifications cover voltage regulation, current capacity, and overall electrical current efficiency regardless of environmental conditions.

When considering the mechanical design of a rugged power supply, look for structurally reinforced components that can endure extensive physical impact, vibrations, shocks, and other occurrences expected in military applications. Secure mounting options and compact forms often allow for added adaptability, especially in military vehicles and confined aircraft spaces.

Two critical considerations for military and similar applications are electromagnetic interference (EMI) and electromagnetic compatibility (EMC). Rugged power supplies undergo rigorous testing to ensure the minimization of EMI emission and promote compatibility with surrounding equipment, preventing disruptions in communication and the functionality of all electronics.

To ensure compliance with stringent EMI/EMC standards, manufacturers use strategic and effective shielding and filtering techniques, integrating these systems with other electronic devices effectively.

Building and crafting power supplies for harsh environments demands a meticulous approach that supersedes conventional power supply designs. When engineers design ruggedized power supplies, the following elements are top considerations — and as someone considering these power supplies, you should ensure the option you choose aligns with them.

To ensure the interoperability and reliability of ruggedized power supplies in military applications, manufacturers must meet military specifications and standards when constructing them. Military standard quality control is in place to guide the design, testing, and performance evaluation of rugged power solutions. There are several standards in place, and these are some to be aware of:

At ACT, we design and manufacture rugged power supplies for the military and other various harsh environment sectors. With decades of experience, we’re well aware of the ever-changing needs and requirements of military technology and the standards that govern power supplies. As a result, we’re prepared to be your go-to option for high-quality, compliant ruggedized power solutions — even when you require custom options, we can design exactly what you need for your application.

We stay current with all relevant materials, design advancements, and manufacturing methodologies, and have our quality system certified to AS9100D and ISO 9001:2015. We also ensure all our products meet the required quality standards, and are designed and built with performance and protection in mind. We strive to exceed product and service delivery expectations and are here to help you find the best power solution for your application.

For high-performing solutions, you can start by browsing our ruggedized power supply products. If you have any questions regarding our production process or would like to discuss custom military power supplies, you can complete our online form to make an inquiry. One of our team members will be in touch!